2/1/11 - Finished construction work document and had it evaluated. Came up with a legitament materials list using an actual companies catalog. Finished details on dispensers.

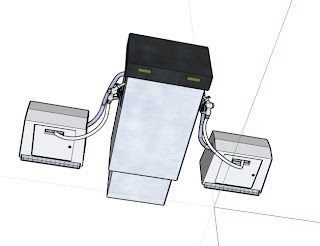

2/4/11 - Added the dispensers to the final 3-D layout. Constructed the floating dock in the layout using MaR's guidelines. I really feel like the design is coming along. Also, I started to add in bathroom appliances for the attendant's house.

2/7/11 - Added water to the entire drawing, researched products for piping. Found cleats for dock on the sketch-up warehouse.

2/10/11-2/13/11 - Absent from school, unable to complete/update any work

2/15/11 - Inserted cleats stratigically into the drawing. Kept them close to where there are pumps rather than all around the dock. I should maybe place them all around the dock incase a boat wants to just get inside the attendants house without getting in the way.

2/18/11 - Worked more on the attendants house in my drawing. No roof so far but I made all of the walls with a 2.5" thickness. The house is to be made of bamboo.

2/21/11 - Inserted windows and researched what types of doors to add into the drawing for the attendant house. Resorted in looking up sketup models for doors.

2/24/11 - Found a couple doors to use. Tested how they would fit inside. Also, AN gave me solar powered lamps in sketchup to use in my drawing. They need no external power source or wiring other than energy from the sun, so I can place them anywhere.

3/1/11 - Inserted lamps into my drawing. They are symmetrically placed along each side of the dock, 9 in total. The drawing is getting so large that the file is very slow, making inserting little details into the drawing a slow and difficult process.

3/3/11 - started to layout the roof of the attendant house. Trying to keep a natural wood theme usinga darker stained bamboo

3/7/11 - still working on the roof in my drawing. It might take another period or two to get it perfected because the file is so slow

3/10/11 - completing the roof of the attendant house today. Recieved help from ms green about the ends of the roof

3/15/11 - drawing is mostly complete. Working on the pipes now this week. I have o connect them to each dispenser and sumps.

3/17/11 - had trouble using the follow me command to connect te pipes. Although it is frustrating, I am working on it little by little, showing progress.

3/21/11 - started working on the sump in a separate file so it would be easier to insert it into the master drawing. Inserted actual diagram images into the middle of the sump.

3/25/11 - finished the sump and inserted it into the drawing. Finished a video of the final product. AN informed me that she gave me the wrong lamps but I did not have the time to change them in my drawing so I am leaving the finished final product as is. Getting ready to test using a video and starting outline for FPUs

3/28/11 - getting ready for FPUs starting this week

3/31/11 - FPUs are in action

Sunday, April 3, 2011

Wednesday, March 30, 2011

MP3: FPU

Task at hand:

Design fuel dock layout, choose piping and other products to use in design, and create final working drawings of those products.

Design Brief:

Design the layout of the fueling station for boaters to access at the Sandy Hook Green Marina year round, and provide the details for installation of the components for the system.

AMC

Specifications –

o Product must safely and efficiently provide fuel

o Design must prevent fuel spills

o Design must minimally interfere with the surrounding ecosystem

o Design must connect with the civil fueling system

o Must be accessible to a trained maintenance staff

o Piping must be able to resist all types of weather extremities

o Design must adhere to the laws and regulations provided by head engineer

o Design must not be prone to any types of large scale contact resulting in damage

o Design and construction cannot damage the park’s environment and ecosystem

o Amount of pumps must correlate with amount of activity or use

o Must have both petroleum and diesel fuel dispensers

o Design must be aesthetically pleasing

o Must be designed for saltwater

Limitations –

o Pumps are only for diesel and petroleum

o Cannot have more than 6 pumps

o Amount of power available is limited by accessibility to central building

o Limited to materials that are non-corrosive in salt water

o Dock design is limited to 100 feet in width, 75 feet in length

Final Solution

Any Questions?

Monday, March 28, 2011

Thursday, January 20, 2011

FPU

Task at hand:

Design fuel dock layout, choose piping and other products to use in design, and create final working drawings of those products.

Design Brief:

Design the layout of the fueling station for boaters to access at the Sandy Hook Green Marina year round, and provide the details for installation of the components for the system.

AMC

Originally Chosen:

Current Layout:

Construction Process:

Piping Transitions:

Piping Product Choice:

Wednesday, January 5, 2011

Piping Transitions

To transition from shore to the dock, the double walled piping will simply continue out of the ground and lead to the docks. The key components are the two transition sumps. One must be placed underground and is called the Onshore Transition Sump in figure A-1. Also in Figure A-1 is the Dock Transition Sump, which would be located inside of the floating dock.

The transition of pipes from the stationary dock to the floating dock is shown in figure A-2 below. The piping is strong but flexible enough to weave down the gangway in a wavelike formation. It is shown below in the aerial view. The pipes are hung using hangers and the details of those are shown

below as well. I will be running both a diesel and petroleum pipes under the gangway so I am planning on have two sets of hangers right next to one another. This will allow the pipes to be replaced easily is something goes wrong with one of them.

| ||||||

| Fig A-1 This drawing shows the major elements of a marina fueling system, including double-walled piping, containment sumps, and support of the piping under the gangway. |

The transition of pipes from the stationary dock to the floating dock is shown in figure A-2 below. The piping is strong but flexible enough to weave down the gangway in a wavelike formation. It is shown below in the aerial view. The pipes are hung using hangers and the details of those are shown

below as well. I will be running both a diesel and petroleum pipes under the gangway so I am planning on have two sets of hangers right next to one another. This will allow the pipes to be replaced easily is something goes wrong with one of them.

|

Subscribe to:

Comments (Atom)